- Home

- Newsletter

- The Importance of Strength Calculation in Valves

The Importance of Strength Calculation in Valves

25/11/2025 - 15:51

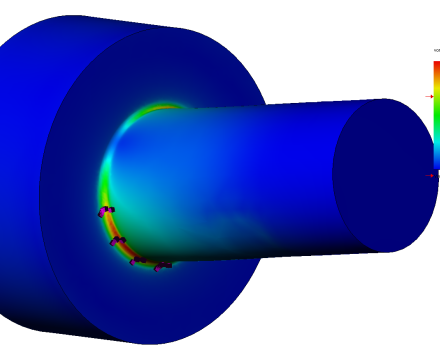

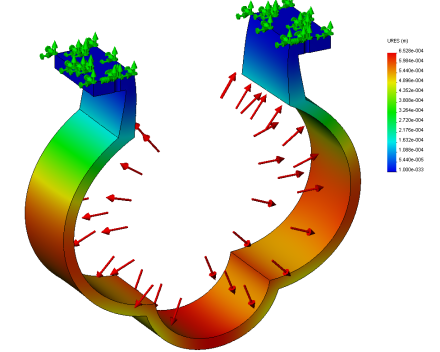

In pneumatic conveying systems, a rotary valve is subjected to constantly varying internal loads. This pressure force - caused by compressed air - reaches at least 1.000 kg. This represents an intense, continuous load on all materials used.

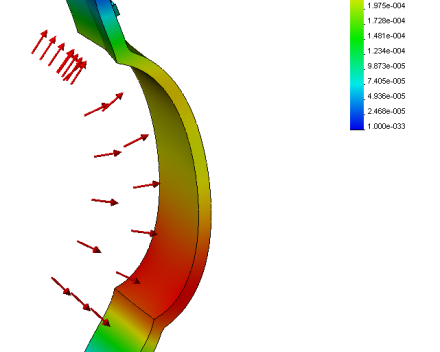

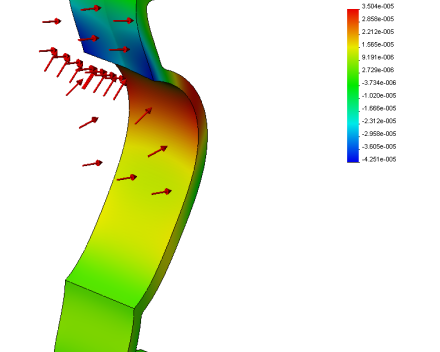

Although this exceptionally high load does not mean that a valve is at risk of bursting, it does mean that the stator, rotor, and flanges are constantly bending, flexing and stretching during every second of operation. Rotary valves are machined to tolerances of tenths and even hundredths of a millimeter. Any small deformation can affect this extremely precise clearance.

Depending on material strength and design, the clearance can:

- Increase: this reduces the efficiency of the valve. The smaller the clearance, the more efficient the operation.

- Decrease: when the clearance eventually disappears, this leads to accelerated wear or - in extreme cases - internal failure.

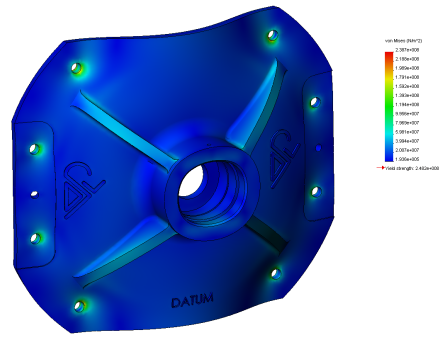

Accurate strength calculation is crucial for the reliability and lifespan of a rotary valve. This applies both to new valves, where the design must from the outset accommodate long-term loads and to overhauls, where corrective recalculations are necessary to ensure that used or replaced components do not deform prematurely.

Strength calculations ensure that:

- Materials and wall thicknesses are correctly selected.

- Deformations remain within safe limits.

- Clearance remains stable and functional.

- The risk of wear, reduced capacity and failure is minimized.

In summary: stronger valve = less deformation = less wear and better efficiency.

A technically well-designed and properly calculated valve is not a luxury, but a prerequisite for a safe, efficient, and durable pneumatic conveying system.