- Home

- Newsletter

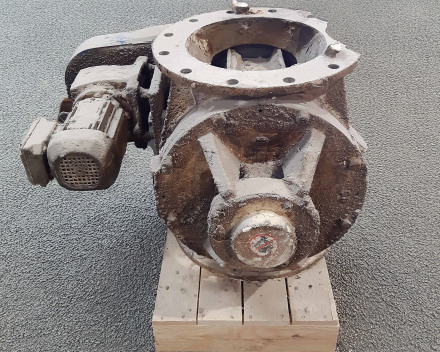

- Reliable valve for adhesive materials

Reliable valve for adhesive materials

21/10/2025 - 08:57

In many process lines, a rotary valve is indispensable. However, as soon as operations involve wet or sticky products, a conventional rotary valve quickly reaches its limits.

Typical problematic materials:

- Wet clay pellets

- Raw materials for gypsum production

- Wet biofuels for pyrolysis plants

- Sticky waste from stone wool production

- Wet and sticky slaughterhouse waste from destruction processes

Why materials adhere

There are four main causes that can lead to accumulation or adhesion of raw materials in a rotary valve:

- Stickiness due to additives – certain auxiliary substances increase adhesion.

- Hygroscopy – the material absorbs moisture and becomes sticky.

- Agglomeration – particles interlock and form clumps.

- Sintering – particles partially fuse due to internal friction or heat.

Each of these mechanisms can result in incomplete rotor emptying and reduced air-tightness.

Four effective solutions against sticking

- Rotor scraper: cleans the stator and flange wall during operation – prevents build-up inside the housing.

- Self-cleaning airlock: each rotor chamber is continuously emptied mechanically – ideal for sticky products.

- Easy-clean airlock: can be quickly and hygienically opened for thorough cleaning between production runs.

- Smooth interior finish: polished or coated surfaces minimize adhesion of product residues.

These solutions can be combined depending on product characteristics, process conditions, and cleaning requirements.

Spotlight on self-cleaning rotary valves

The problem: the rotor is not fully emptied during operation. This leads to build-ups, blockages, and ultimately reduced efficiency or even unplanned downtime. Self-cleaning rotary valves prevent these issues by continuously emptying the rotor mechanically during operation. This ensures that sticky material has no chance to accumulate.

Advantages:

- Consistent and reliable operation

- Fewer blockages and less maintenance

- Higher process stability under demanding conditions

Curious how it works?

👉 Click here to see the operating principle of a self-cleaning rotary valve in action.