- Home

- Newsletter

- Thermal spraying

Thermal spraying

31/10/2025 - 14:00

Extreme wear on rotary valves: causes and solutions

In certain applications, rotary valves are subjected to heavy loads, resulting in extreme wear. In some cases, a refurbishment is required after just a few months - or even weeks.

When such exceptional wear occurs, it is essential to thoroughly investigate the causes.

Often, it is a combination of abrasive material and unwanted air turbulence that accelerates the wear. However, the correct choice of valve type and the way it is operated also play an important role.

By “reading” the valve, it is often possible to identify which factors are causing the wear and which adjustments will yield the greatest improvement. This way, service life can be extended and the durability of the entire installation increased.

Once the optimal configuration has been achieved, the lifespan can be further extended by applying hard, wear-resistant materials to critical components.

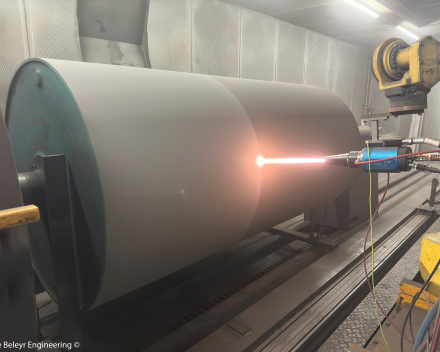

One of the most effective techniques for this is thermal spraying—the hardest and most durable form of surface protection.

Why thermal spraying?

With the HVOF process (High Velocity Oxy-Fuel), an extremely wear-resistant and corrosion-resistant coating is applied to the inner diameter of the rotary valve. This technique offers significant advantages compared to untreated or purely machined surfaces.

The benefits at a glance

Extreme wear resistance

The HVOF coating with tungsten carbide is extremely hard (up to 74 HRC) and provides optimal protection against wear from abrasive materials and erosion from airflow or pressurized fluids.

➡️ Less maintenance, less downtime.

Longer component life

The coating maintains the original dimensions and protects the base materials—even under intensive use.

➡️ Fewer overhauls and replacements.

Lower friction, better performance

A smooth, uniform surface reduces friction between the rotor blades and stator walls.

➡️ Better sealing and dosing, lower energy consumption, and less heat generation.

Corrosion resistance

Ideal for humid or aggressive environments.

➡️ Less rust, chemical attack, pitting and micro-cavities.

Precision restoration during overhaul

Even worn rotary valves can be restored. Through thermal spraying combined with precise grinding or honing, we can bring components back to their original fit—often without full replacement.

✅ Extend component life. Increase reliability. Save on maintenance. All with one durable intervention!